|

History of the Mines

Please note this page is

constantly being updated

Craig y Ddinas, nowadays a popular venue for walkers, climbers, gorge

walkers and cavers, was once a thriving hub of industrial activity. The

nearby Glyn Neath Gunpowder works extends for a distance of about 2 miles

along the Afon Mellte, and the Sychryd Gorge was a centre for mining of

silica rock, a substance which for very little work could be made into a

high quality firebrick suitable for a variety of uses from domestic

fireplaces to lining iron and steel furnaces.

So high was the quality of these that they actually became known as “Dinas

Bricks” and were exported to both Europe and America.

The silica

rock was discovered in the 1780s and exploited thereafter, in 1807 a

tramway was installed to take the product to the Neath canal.

The first large scale

mining at Dinas was by a William Weston Young. Young was born 20 April

1776 into a devout Quaker family. Educated at Gildersome Quaker boarding

school in Yorkshire, he gained a rudimentary knowledge of science

which he was to apply in his invention of the silica firebrick.

After a flustered attempt to emigrate to America in 1794, Young settled

back in Bristol, found employment and married fellow Quaker, Elizabeth

Davis, in April 1795. In 1798, Young had acquired the financial backing to

lease a farm and water mill from John Llewellyn of Ynysygerwn, at

Aberdulais, in the Neath Valley. After a lucrative start to his new

venture as a miller, corn-factor, and farmer, some unfortunate business

dealings brought him to bankruptcy in May 1802.

He managed however to secure some funding from a fellow Quaker with which

he managed once again to set himself up in business and went on to be a

potter and wreck raiser amongst other things. Unfortunately he had some

bad experiences where fine porcelain was ruined in the firing.

Young's experience of firing ceramics, together with his familiarity with

the region as a local surveyor and his amateur interests in geology

enabled him to conceive of a heat-proof, blast-furnace brick, using silica

found in large deposits at the head of the Neath Valley. The process of

"vitrifying" the walls of a ceramic brick-built furnace had been patented

by William Harry, of the Swansea Valley in 1817, but Young's solution was

to build the whole furnace from a "silica firebrick," made with a 1%

addition of lime, to bind the blue-grey "clay" of the Dinas rock. The idea

being that the interior of the blast furnace would vitrify and be vastly

more durable and ultimately economical, than a mere veneer of silica

within a comparatively fragile ceramic shell. Young made early experiments

with the recipe and fired his trial bricks at the Nantgarw Pottery kilns,

while he and Pardoe finished the Billingsley porcelain for sale between

1820 and 1821 when he finalised his recipe.

In 1822, Young applied to the Marquis of Bute to lease the lands near

Craig y Dinas, Pontneddfechan, in the upper Neath Valley for a period of

twenty-one years.

On 19 October 1822, the Dinas Fire Brick Co. was established in a

partnership involving David Morgan, a Neath Ironmonger, John Player and

Joseph Young and a brickworks was built at Pontwalby, about a mile down

river from Craig-y-Dinas.

The company sold bricks to industry across the world, and was transferred

through many hands, but the Young family, held their shares throughout,

finally passing via Joseph Young to his son William Weston Young Junior

(1798–1866). From "The Dinas Firebrick Co." to "John Player & Co." in

1825, to "Riddles, Young & Co." in 1829 and finally, becoming world famous

as "Young & Allen" in 1852, the company brochure later mentions that it

had supplied firebricks to Swansea's White Rock Copper Works for forty

years.

Initially, extraction was by opencast working marked on old maps

as "Quarries" and on the abandonment plans as "old workings". During this period of working the mines produce was trammed out of the

upper mine entrance and across a bridge over the Afon Sychryd, From here

it entered a tramming tunnel, now known as Bwamaen or Middle Silica Mine, and

then out of a lower entrance. The underground route descends as a gentle

inclined passage. From there it re-crossed the Afon Sychryd by another bridge, the piers for which can still be seen at

an area where the track widens and there is a picnic table.

From here followed the north bank along a tramway which extended for about

two miles. A branch to the south ended at a loading bay at the Great

Western Railway while the main tramway ended at a loading bay south of the

Pontneddfechan Road, later lost in road improvements.

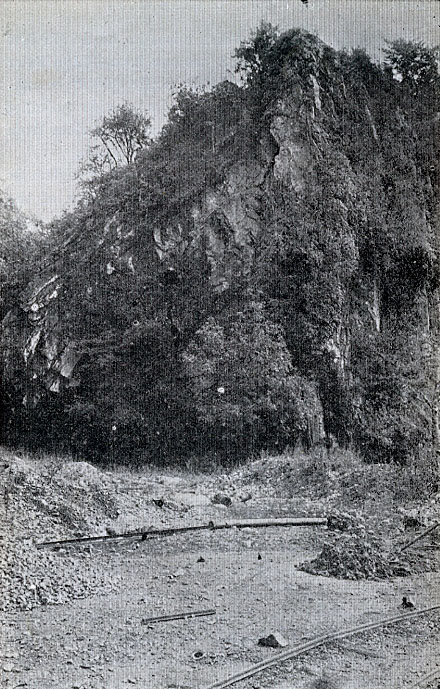

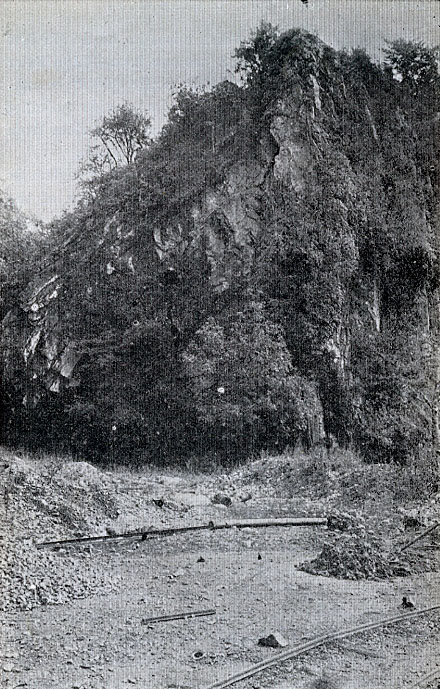

Below is a 1908 photograph of the Bwamaen rock

with the mine tramway in front. The original is incorrectly

captioned as "Craig-y-Dinas inferring that its Dinas Rock.

Courtesy Mike Stokes.

Mining continued until about 1921 when the mines closed for while, but

restarted in 1930 when a new 2 ft tramway was laid from the mine along the

north bank of the Afon Sychryd. Here mine trucks emptied into a hopper

where the produce was drawn off into trucks waiting below. Empty

trucks were pushed past the hopper along a continuation of the

tramway following a ledge cut into the rock

which can still be seen, but each end has

now been blocked off for safety. Precise information is scant and

this is put together from a study of old maps and other information.

A problem here was a sudden drop of about 50

feet adjacent to a water fall which made access to the mine

difficult. This was solved by the erection of an

incline ramp using steel girders concreted into the rock.

Some accounts describe the 'incline ramp' as an

ore chute with produce going directly into lorries below, it may

have served both purposes with trucks being raised by a winch and

cable to get materials up to the mine, but in the absence of any

photographs or factual description, its impossible to tell. There is

no way even a small lorry could turn around in this area at what

would have been the base of the chute, however there was plenty room

lower down opposite the bridge from the old tramming level. (By the

current picnic bench). Lorries could have turned around there and

then reversed backwards up to the chute.

Haulage above the incline ramp was by horses up until the time of the second word war

when two locomotives were purchased.

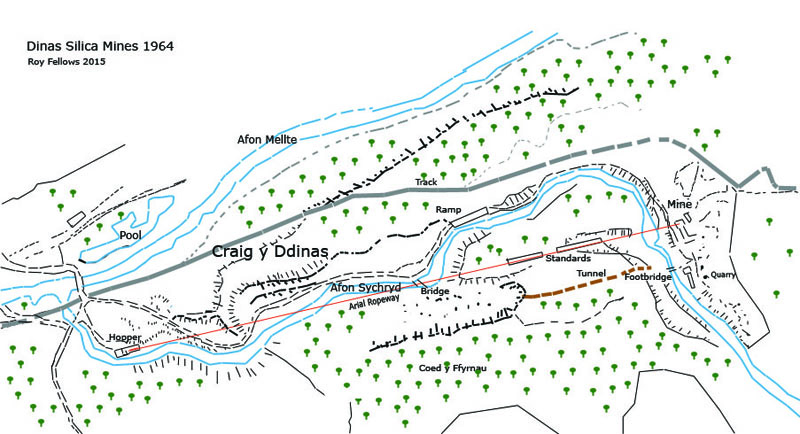

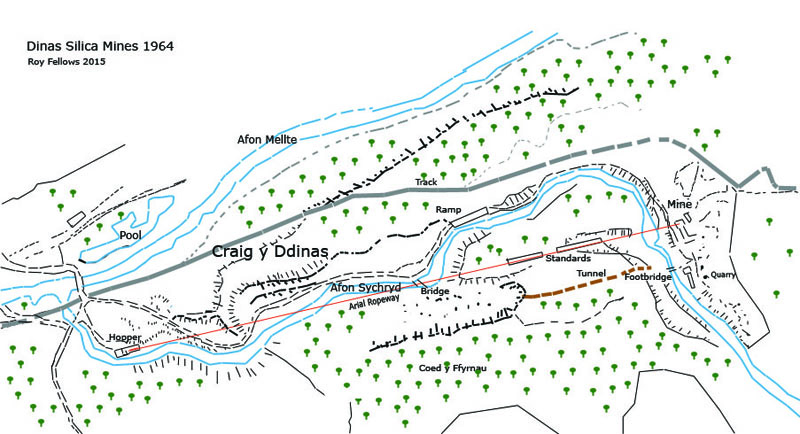

The final phase of working by

Richard Thomas and Baldwins Ltd included the installation of an ariel ropeway

as illustrated in the little plan below. Many features associated with

this can still be identified by anyone prepared to do a bit of scrambling.

This effectively made the incline ramp redundant and it was boarded over

to make a pedestrian walkway, it may also have taken a light vehicle.

An account by A D Semmens visited to the mine in 1963 makes interesting

reading:

The mine closed for production in September 1962, being officially

"stopped temporarily". Only the manager and one other man were

working here in August 1963, and the manager was delighted to take

me down the mine to see his one remaining locomotive. We proceeded

to light acetylene lamps, and wound our way down the rather wet

workings to a dry spot about four hundred yards down where stood 69,

a four-wheel diesel, Ruston & Hornsby 201996 of 1940. Very obviously

ex−Government,

Mr. Thomas said it had been received from a London dealer about

three years ago; another Ruston diesel had gone back to him in part

exchange. Two other Rustons had been sent down to RTB’s Landore

works when the mine closed, as both wanted attention, and they are

now in store there following overhaul. A visitor

to the mine in May 1961 noted three Ruston diesels – 217980/46,

223730/46 and 277292/49 – but not the one

cited above which presumably was down the mine at the time.

The mine

has been worked since the 1830s and there are some fairly steep

cable inclines going down into the bowels, most of which are now

flooded. The present modus operandi is cable operation to an adit

top immediately above the one which now forms the mine entrance,

where a very small gantry line leads to the top of the aerial

ropeway. The latter climbs up one side of the hill, and from there

the topmost pylon carries the full strain of the drop to the bottom;

the manager said it was the longest aerial ropeway span in the

country. he is proud of his mine although its future is one with a

large question mark. Quartzite is extensively used for steelworks

furnace linings but demand has dropped sharply, for RTBs new

Spencer works uses none at all.

There is an underground incline with an

electrically powered winch still to be seen underground, and this

could be what Semmens is referring to, with produce being trammed to

an area above the mine for offloading into the buckets of the rope

way. A lot of this unfortunately is speculative.

The mine finally closed in 1964

The surface was stripped of locomotives, trams, Arial ropeway and all that

could be moved by Eastman’s of Swansea in the 1970s, but the incline ramp

in deteriorating condition remained on site for about another ten years.

The mine buildings were demolished possibly earlier and all the

rubble dumped into the mine.

A visitor to the site gives the following graphic description of

the ramp:

I remember it vividly!

It had steel column uprights, the burnt-off bases of which are still

visible in places in the ravine and river bed. There was a deck which

sloped at about 25, maybe 30 deg, rising from west to east and about 8ft

wide of transverse timbers, probably no more than 3in thick and with a

couple of inches between each timber. There were no obvious signs of

sleepers, rails, or bolt holes but it did have a steel handrail which is

what makes me assume it was mainly a pedestrian access.

By 1974, some of the deck timbers were rotten and a few broken and

missing, so it was necessary to walk up with your feet above one of the

two longitudinal RSJ's which were a couple of feet in from the edges. My

recollection of the overall length is less clear but I'd guess at 150ft

which suggests a rise of around 50ft.

Now everything lies quiet and idle with nature gradually claiming it all

back. Underground little has changed bar the inevitable roof falls and

flooding of the lower workings which have become a popular venue for

divers.

There is a remarkable collection of

historical photographs showing the mine at work here:

https://www.flickr.com/photos/125139274@N05/albums/72157652323953051

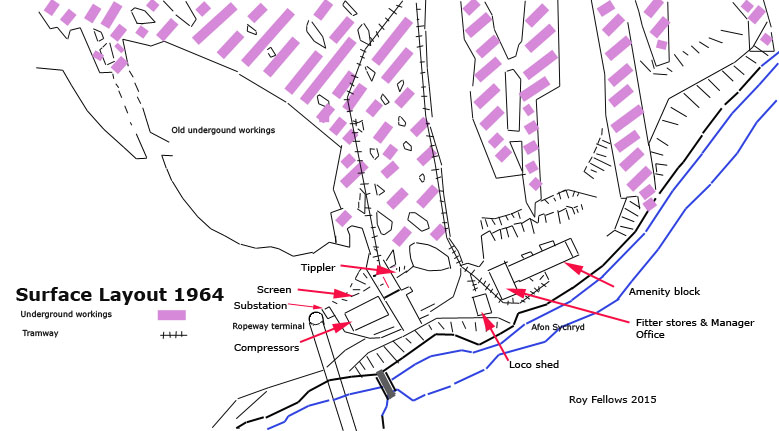

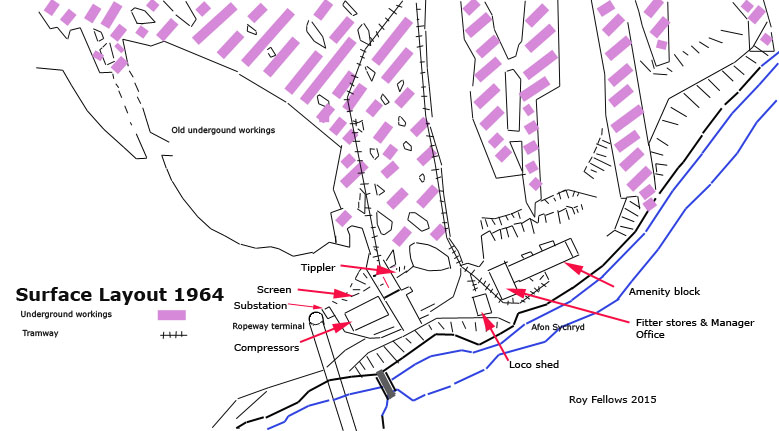

Surface Layout 1964 scanned from abandonment plan.

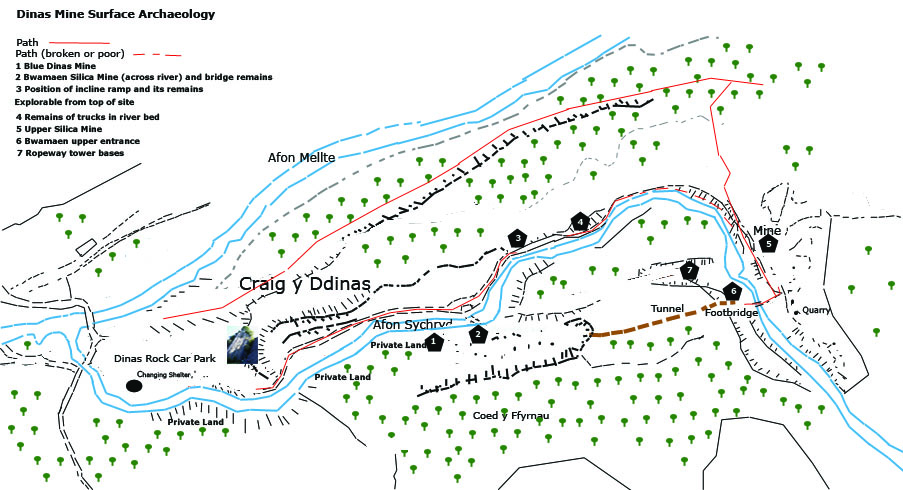

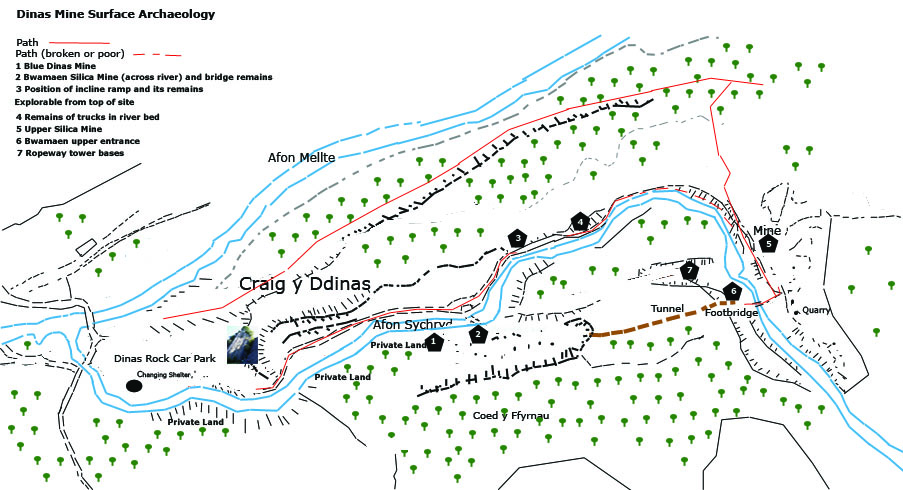

From the Dinas Rock car park its but a short walk along the old tramway

route, now a made up path, to the start of a the incline ramp where there

is a large concrete area. On the way, the visitor will have passed on the

opposite river bank the Blue Dinas Silica Mine and the uprights of the

tramway bridge from Bwamaen. Please note that Blue Silica is not part of

Craig y Ddinas Mineral Estate but private property.

If one takes the northern path above the car park after a very steep climb

a descent to the right will reach the Upper Mines. Here one can follow the

Afon Sychryd downstream past a series of old trucks put the to support the

bank but now mostly washed away, eventually reaching the top of the

incline ramp and the rock cut ledge.

Back at the mine there is a footbridge which leads to the upper entrance

of the tramway tunnel, again this is not Craig y Ddinas property.

If you are overcome with curiosity about what its

like inside the tunnel then here goes, but this is not our property

and is currently gated so no access is possible.

Not mine related but here is the rock from which the Bwamaen Mine

takes its name

There is also a nice waterfall close to the car park behind the

changing shelter

Here is a link to photographs taken by Mike Stokes in 1992. The rake

of trucks by the river bank is still intact.

https://www.flickr.com/photos/opobs/sets/72157636747245343

|