|

Images

below are courtesy of Don Richardson (unless otherwise stated)

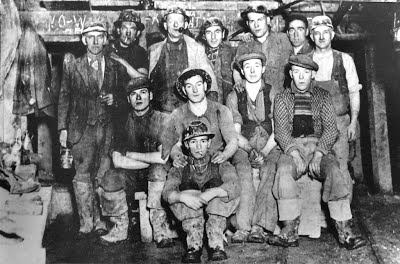

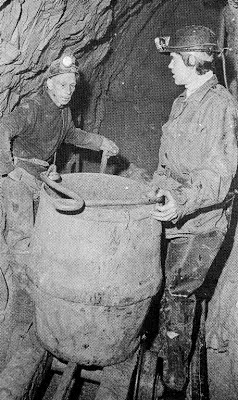

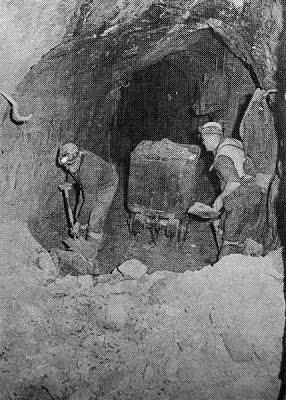

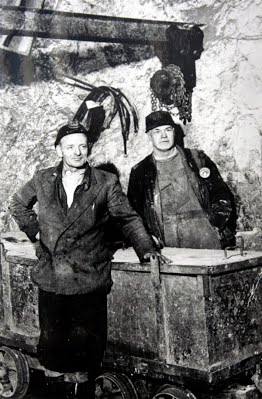

Halkyn

Miners in the 1930s. Location of workings unknown.

Anyone

recognise the place or the people?

Don Richardson was

electrician at Halkyn Mines from 1940 to 1987 when the mine finally

closed. Don managed to save a collection of photographs and papers

relating to the mine. He kindly agreed to talk about his years spent

underground with the writer in 2011, and also permitted the copying of

his collection. The majority of the photos are shown, with Don's

consent, on this page. Some are unique images from the 1930s and may not

have been seen before.........

Notes

taken during a conversation with

Don

Richardson at his home in Holywell

Sept 8th 2011

Don was

aged 86 at the time of the visit. His memories were clear and he was happy

talking about his years at Halkyn Mines.

It was

first pointed out that “The Milwr Tunnel” book had two errors which Don

wished to correct:

The book

wrongly states that the round tallies were used at Olwyn Goch Shaft and

the hexagonal tallies at Pen-y-Bryn. Both tallies were actually used at

both shafts: Each miner had their own round tally, which they used when

clocking on. The hexagonal tallies were then picked off the rack by each

miner before entering the cage. These were picked in numerical order. At

the end of shift, men were taken up the shaft in the same order as they

went down, thus encouraging men to arrive promptly at the start of each

shift.

The wooden

galvanometer shown in the book was not of the type used by Halkyn Mines.

Don produced his own ohmmeter as used at the mine (image below).

Halkyn

Mines ohmmeter used to test shot wiring before blasting

Don began

work for Halkyn Mines at the age of 15 in 1940 following his father

Alberts footsteps. Albert moved from Staffordshire as an overman to work

at Bettisfield Colliery and later joined Halkyn Mines. Don's father is

pictured in the photo on page 20 in “The Milwr Tunnel” 2nd edition,

shown below (bottom right). Other people remembered by Don in the same

photo are back row, from the left: Cecil Lloyd, Mr Powell, Ben Casey.

120ft

below tunnel level, prior to blasting into the lake at Powell's

lode. Photo: Glynn Morris

The large

galvanised tanks above Powell's Shaft stored water used for cooling the

large compressor installed at tunnel level below. When installing the

pumping machinery in Powell's Lode at -120ft below tunnel level, a

submarine torpedo tube was installed between the new pumps and the rock

face prior to the final blasting through to the lake.

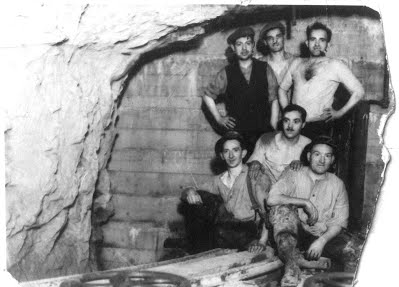

Several

German Prisoners of War were employed by Halkyn Mines. Amongst these

were Walter Blok of Mold and Herbert Jagusch. Herbert married a girl

called Maude, also from Mold. Although now living in Germany, they

return each year to visit friends and relatives and he maintains a keen

interest in local mining.

Herbert

Jagusch and his wife Maude pictured with one of his superb anthracite

carvings.

The

carving was presented to Wrexham Museum who have held it in storage ever

since!

Photo: Cris Ebbs

When the

Milwr Tunnel reached Cadole in 1957, driving was finally stopped. The USA

had been stockpiling ore but released in onto the market causing a slump

in UK prices. Halkyn Mines continued producing ore that went for smelting

to Walker, Parker in Chester, but the operation was then losing money.

With ore

prices being so low, the mine began quarrying a pure form of limestone.

The main extraction area at Hendre known as 'The Quarry', had two main

tunnels connecting the many chambers, one known as Catholics, the other

as Protestants.

Limestone

extraction at "The Quarry"

At

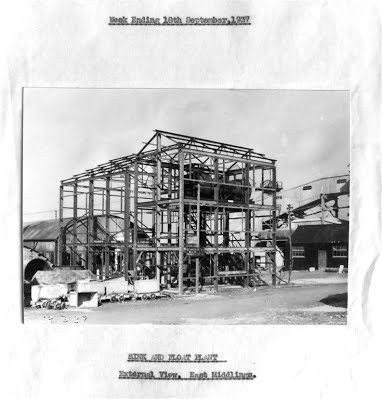

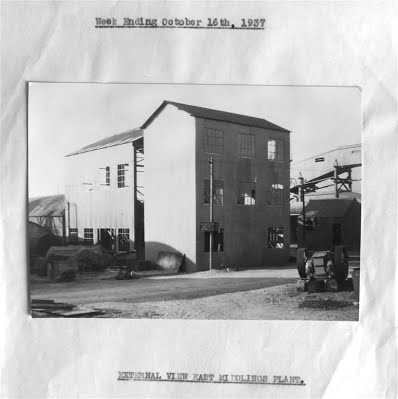

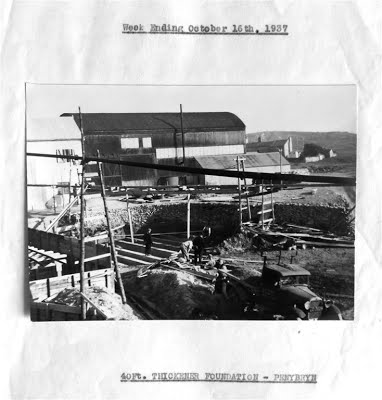

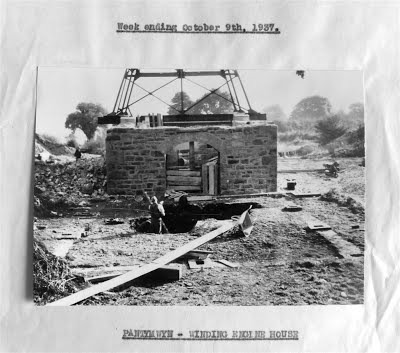

Pen-y-Bryn Shaft in 1937 an experimental melting (not smelting) plant was

installed. The company used the plant to separate brass from builders

waste. The brass was then made into ingots of approximately 15” x 4” x 4”.

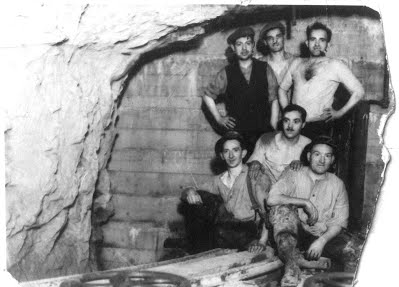

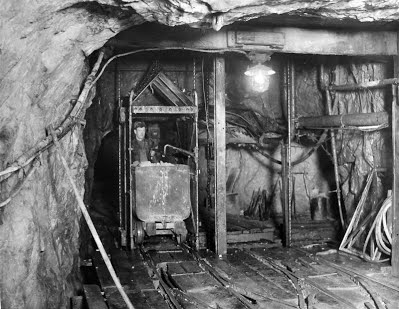

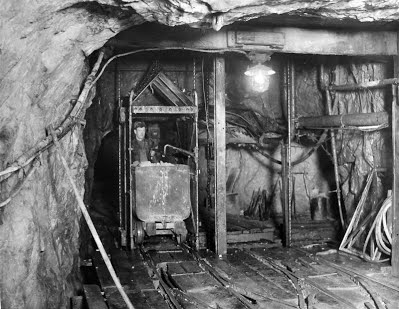

Pen-y-Bryn shaft bottom in the 1930s

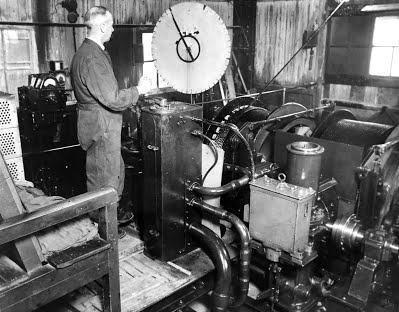

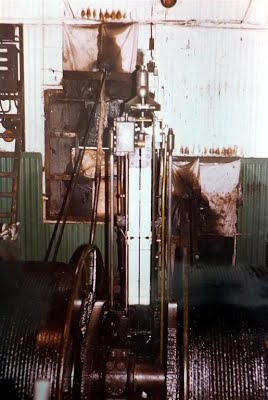

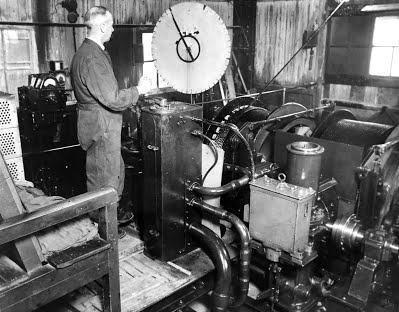

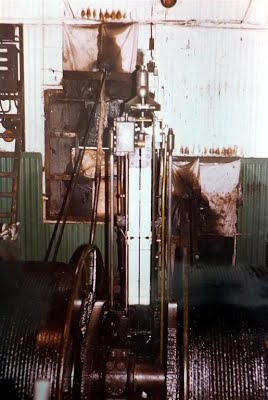

Pen-y-Bryn shaft winder 1930s

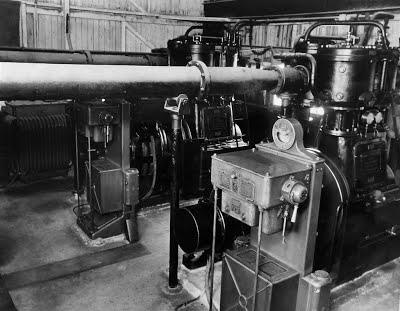

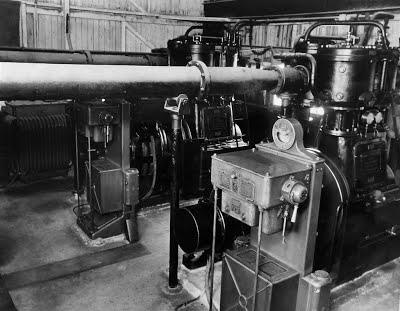

Pen-y-Bryn shaft compressor 1930s

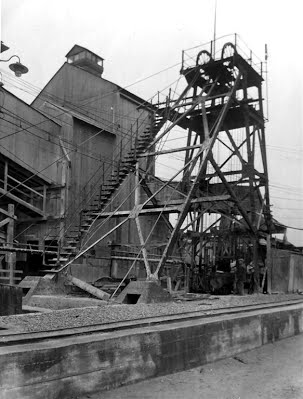

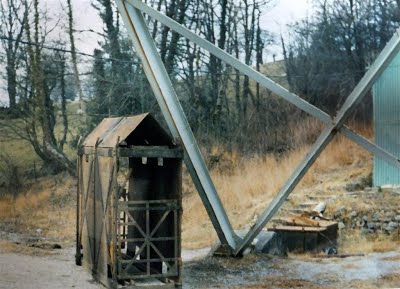

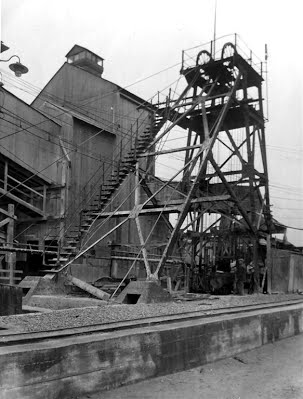

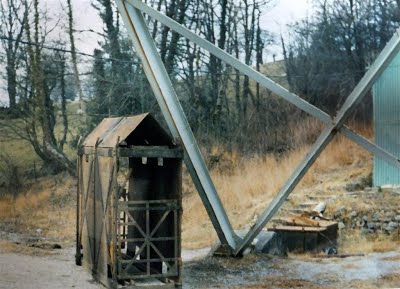

Pen-y-Bryn shaft headframe 1930s

Clearing snow at Pen-y-Bryn

Water

for processing on the surface at Pen-y-Bryn Shaft was supplied by a pump

installed in a sump close to the bottom of the shaft. Pen-y-Bryn Shaft

was stripped out in 1980 when the hoist was taken by Greenfield Heritage

Centre. The main drive shaft for the winder now lies at the entrance to

the centre (image below).

Pen-y-Bryn main drive shaft at Greenfield

Before the

mine finally closed in 1987, the workforce of just six men were given the

job of filling or capping many of the open shafts at surface. A company

director arrived to see a shaft being treated and was taken to Conquerer

of Wales Shaft near Pantymwyn. When invited to take a closer look down the

shaft he declined, commenting “It's too dangerous”. When Don Richardson

was told of this, he pointed out that if it was too dangerous for the

director, then it was too dangerous for the men, and requested danger

money. Mine Manager Mr Bowstred agreed and a phone call later the men were

offered £20 each per shaft on top of their wages.

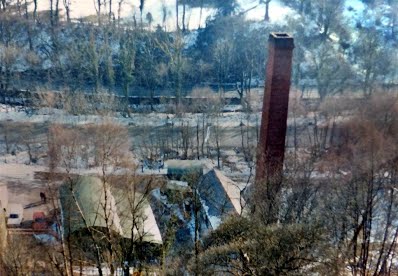

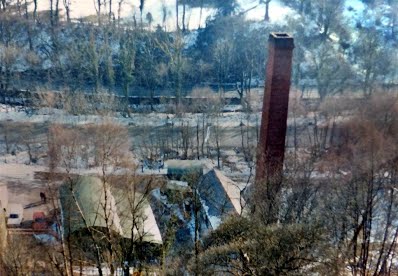

The

brick chimney next to the adit entrance of Olwyn Goch Shaft (image

below) originally served a steam winder at the shaft. When the mine

finally closed, Don was asked to burn many unwanted company documents at

the foot of the chimney. Recognising the importance of some, he asked if

he could keep a selection of photographs.

Olwyn Goch shaft chimney

Don stated that

Halkyn Mines was a very happy work place (confirming the statement by

John Bellis). Although Don was an electrician, he undertook many

different jobs as needs dictated.

When McNabb left the

company, he left his Triumph motorbike, which was in good condition, and

never returned for it.

In 1953 at Olwyn Goch

Shaft a fatality occurred. A guide wire in the shaft had broken and as a

result the cages were not operating. Men therefore had to climb the

ladders in the shaft. One man suffered a heart attack part way to

surface and died on the spot.

Together with those

above, the following photographs represent most of the Richardson

collection.......

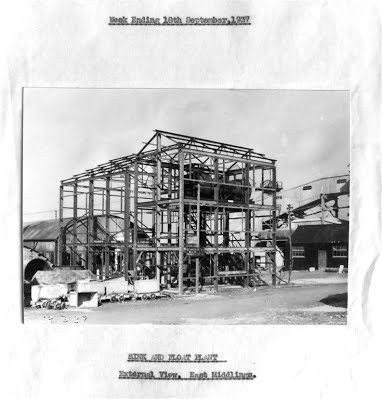

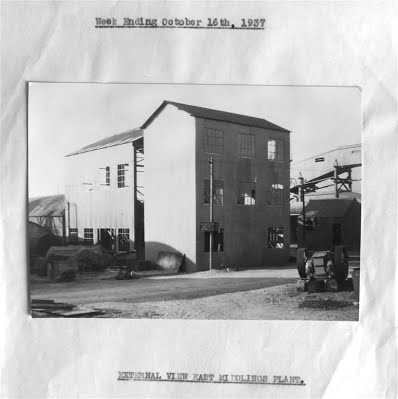

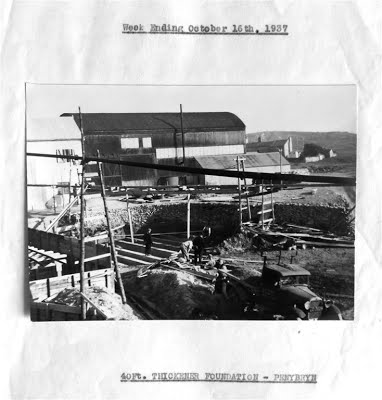

Pen-y-Bryn mill 1937

Pen-y-Bryn mill 1937

Pen-y-Bryn mill 1937

Pen-y-Bryn mill 1937

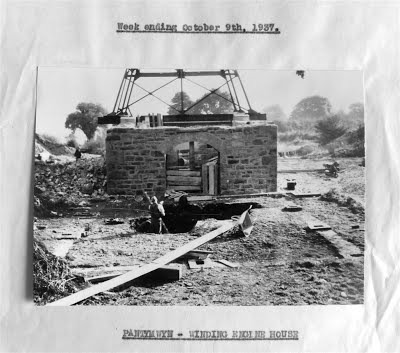

As the Milwr Tunnel advanced southwards, it became necessary to move the

surface milling complex. In 1934, operations moved from Pen-y-Bryn Shaft

at Halkyn, to Olwyn Goch Shaft at Hendre. Subsequently, Cae Mawr Shaft at

Pantymwyn was prepared as a main hauling shaft. But although a winding

shed and headframe were completed, the project was abandoned. The

following four photographs show Cae Mawr Shaft during being prepared.....

Cae Mawr Shaft, Pantymwyn 1937

Cae Mawr Shaft, Pantymwyn 1937

Cae Mawr Shaft, Pantymwyn 1937

Cae Mawr Shaft, Pantymwyn 1937

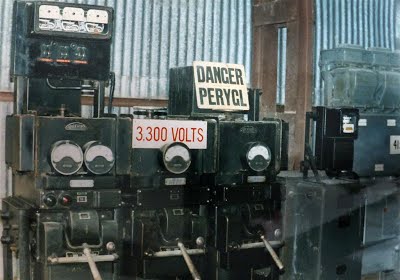

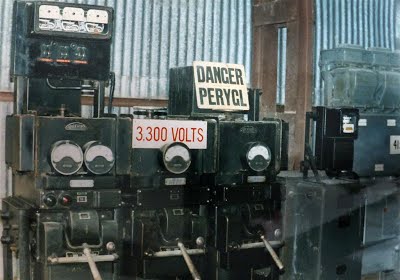

Olwyn Goch shaft charging bay

Olwyn Goch shaft winding shed. Don Richardson and Cyril

Jones

Olwyn Goch shaft winding shed

Shaft speed indicator at Olwyn Goch winding shed.

Speeds over 12 feet a second triggered a bell to ring.

If the speed was not slowed down by the winch operator, power to the

winch was cut off.

Olwyn Goch shaft winding shed

Olwyn Goch shaft mill

Dismantling of Olwyn Goch winding shed and headframe

1987

Guide wires in Olwyn Goch shaft

Shaft cage removed from Olwyn Goch shaft 1987

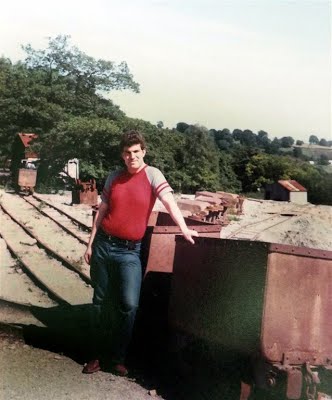

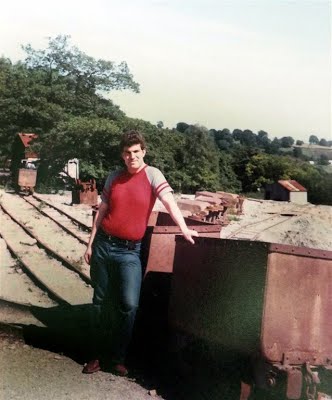

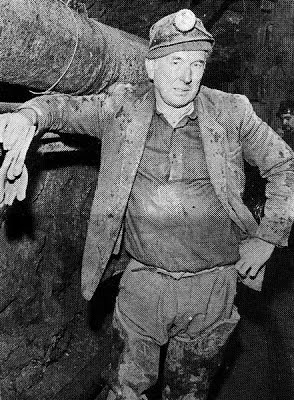

Don

Richardson during the dismantling work at Olwyn Goch 1987

Top of Olwyn Goch headframe after dismantling 1987

Sealing

of of Olwyn Goch shaft 1987

Sealing of of Olwyn Goch shaft 1987

Dismantling of Olwyn Goch winding shed 1987

Dismantling of Olwyn Goch winding shed 1987

Don's son Robin Richardson at Olwyn Goch Shaft 1987

Olwyn Goch sub-station 1987

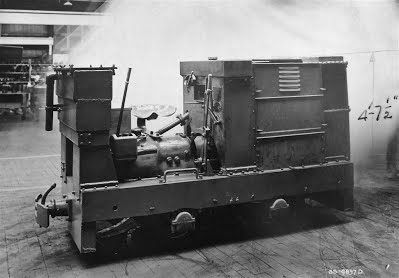

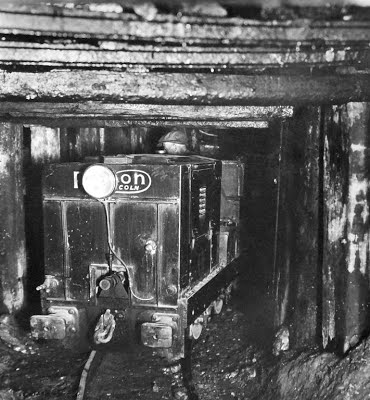

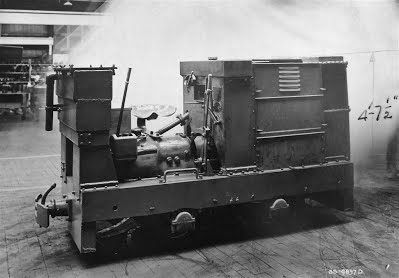

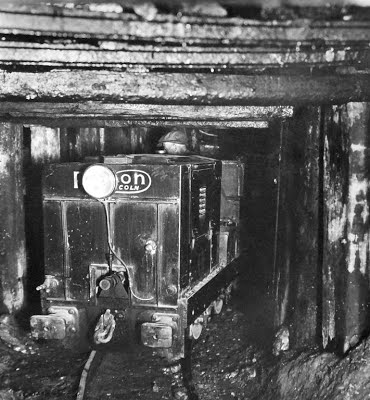

New diesel loco ready for service at Olwyn Goch

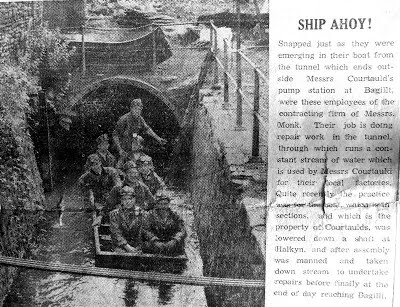

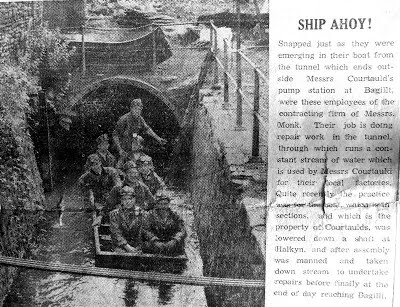

Maintenance team exiting Milwr Tunnel portal. From a

newspaper article

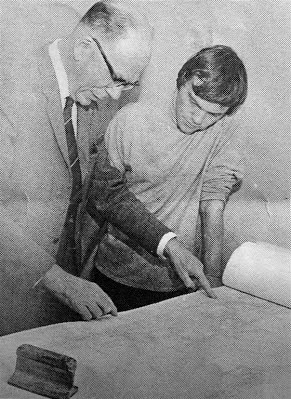

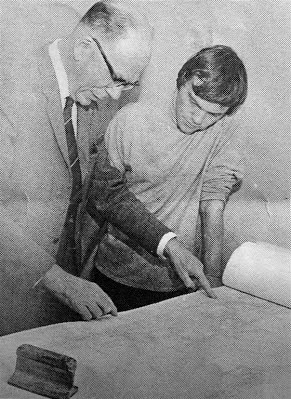

Mine Manager Mr Bowstred and a student from Leeds

examining mine plans

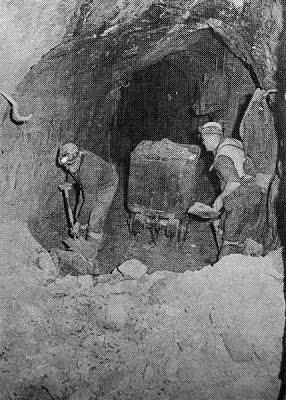

Mucking out in Lode 530 (Pant-y-Buarth Lode)

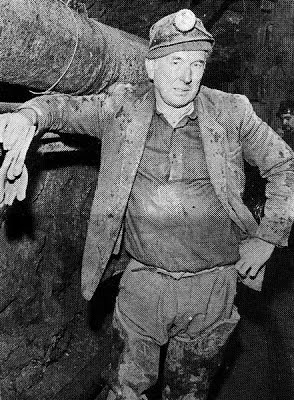

Foreman John Bellis

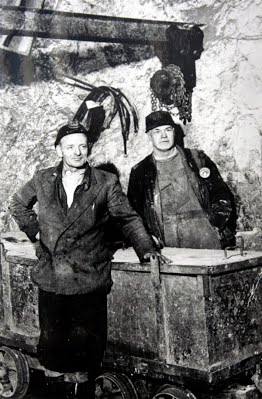

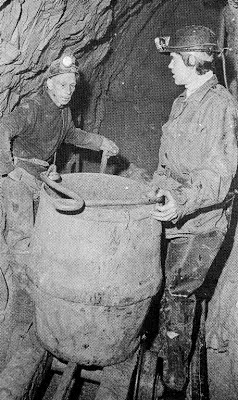

Loading a kibble in Lode 530 below tunnel level

? and Jim Hoole (on right)

The location of this photograph is uncertain, but could be the Rhosesmor

Branch of the Milwr Tunnel

With sincere thanks to Don Richardson for his kindness and generosity

|